Artificial Intelligence in the Food Industry: Automating Production Processes and Controlling Quality with Maximum Precision

The food industry is undergoing a significant transformation, driven by advancements in technology, particularly artificial intelligence (AI). As consumer demands evolve and the need for efficiency increases, AI is stepping in to automate production processes and enhance quality control. This article explores how AI is reshaping the food industry, providing insights into its applications, benefits, and real-world examples.

The Role of AI in Food Production

AI technologies are being integrated into various stages of food production, from sourcing raw materials to processing and packaging. The primary applications of AI in this sector include:

- Predictive Analytics: AI algorithms analyze historical data to forecast demand, helping manufacturers optimize inventory and reduce waste.

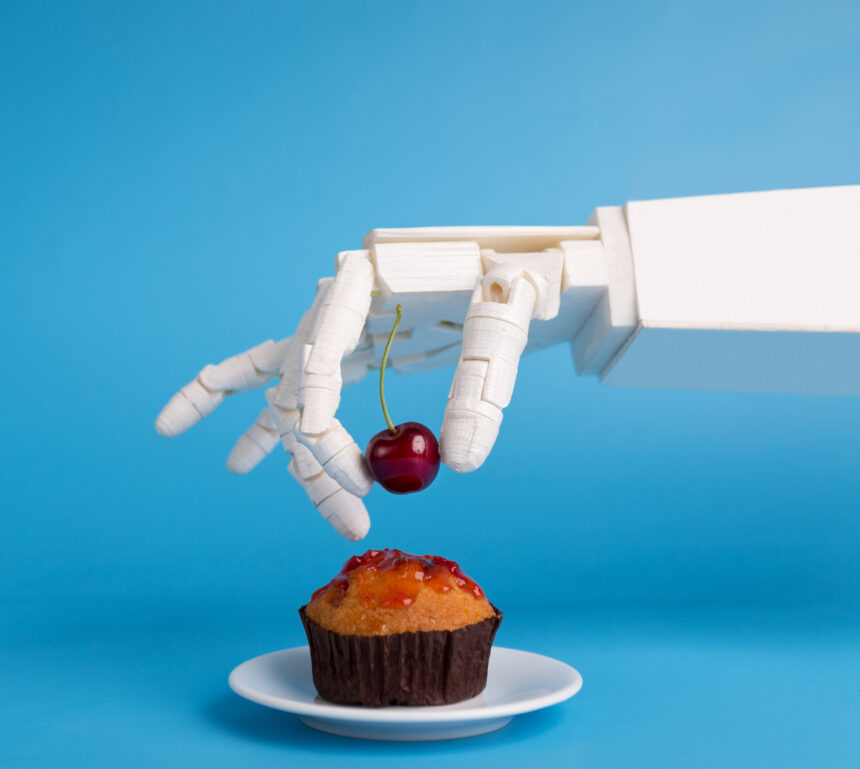

- Robotics and Automation: Automated systems powered by AI are used for tasks such as sorting, packing, and even cooking, increasing efficiency and reducing labor costs.

- Supply Chain Optimization: AI enhances logistics by predicting delays, optimizing routes, and managing supplier relationships.

Enhancing Quality Control with AI

Quality control is paramount in the food industry, where safety and compliance with regulations are critical. AI technologies are revolutionizing quality assurance processes through:

- Computer Vision: AI systems equipped with computer vision can inspect products for defects, ensuring that only high-quality items reach consumers.

- Data Analysis: AI analyzes data from various sources, including sensors and production equipment, to identify anomalies and predict potential quality issues before they arise.

- Real-time Monitoring: Continuous monitoring of production processes allows for immediate adjustments, maintaining product consistency and safety.

Case Studies: AI in Action

Several companies have successfully implemented AI technologies to enhance their production processes and quality control. Here are a few notable examples:

1. Nestlé

Nestlé has embraced AI to streamline its supply chain and improve product quality. By utilizing predictive analytics, the company can forecast demand more accurately, reducing food waste and ensuring that products are available when consumers need them. Additionally, Nestlé employs AI-driven quality control systems that use computer vision to inspect products on the production line, significantly reducing the rate of defects.

2. Tyson Foods

Tyson Foods, one of the largest food producers in the world, has integrated AI into its operations to enhance efficiency and safety. The company uses AI algorithms to analyze data from its processing plants, identifying patterns that help optimize production schedules and reduce downtime. Furthermore, Tyson employs AI for real-time monitoring of food safety standards, ensuring compliance with health regulations.

3. Blue River Technology

Blue River Technology, a subsidiary of John Deere, has developed AI-powered solutions for precision agriculture. Their “See & Spray” technology uses computer vision to identify and target weeds, allowing farmers to apply herbicides only where needed. This not only reduces chemical usage but also enhances crop quality and yield.

Benefits of AI in the Food Industry

The integration of AI in the food industry offers numerous benefits, including:

- Increased Efficiency: Automation reduces the time and labor required for production processes, leading to faster turnaround times.

- Cost Savings: By optimizing supply chains and reducing waste, companies can significantly lower operational costs.

- Improved Quality: AI enhances quality control measures, ensuring that products meet safety standards and consumer expectations.

- Data-Driven Decisions: AI provides valuable insights that help companies make informed decisions regarding production and marketing strategies.

Challenges and Considerations

Despite the advantages, the adoption of AI in the food industry is not without challenges. Companies must consider:

- Initial Investment: Implementing AI technologies can require significant upfront investment in infrastructure and training.

- Data Privacy: The collection and analysis of data raise concerns about privacy and security, necessitating robust data protection measures.

- Workforce Impact: Automation may lead to job displacement, requiring companies to invest in retraining and upskilling their workforce.

Conclusion

Artificial intelligence is revolutionizing the food industry by automating production processes and enhancing quality control with unprecedented precision. As companies like Nestlé, Tyson Foods, and Blue River Technology demonstrate, the integration of AI can lead to increased efficiency, cost savings, and improved product quality. However, businesses must navigate the challenges associated with AI adoption, including initial investments and workforce implications. As the food industry continues to evolve, embracing AI will be crucial for companies aiming to meet consumer demands and maintain a competitive edge in a rapidly changing market.